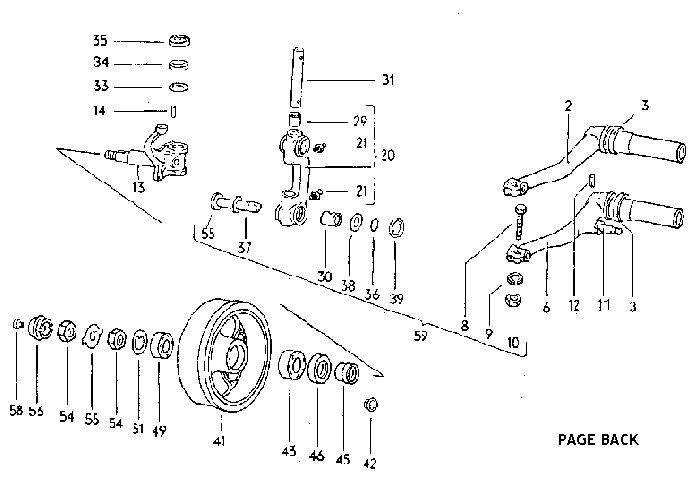

The link pins have a helical groove in their shaft, which engages with the pinch bolts that hold the torsion arm link assembly to the torsion arms. This allows adjustment to eliminate play. Before attempting to adjust the link pins clean off any hard grease, or road dirt, that may have accumulated and pump grease into the two grease nipples until fresh grease oozes out of the joints.

Adjustment of VW Beetle front suspension Link-Pins.

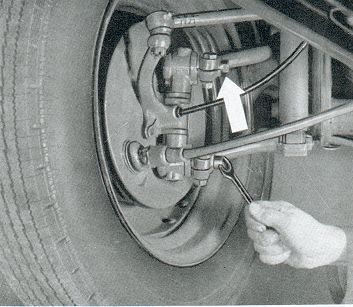

To adjust the link pins slacken the pinch bolts located at the end of the torsion arms and with a spanner, on the flats at the end of the link pins, fully tighten. Then slacken the adjustment about one eighth of a turn and finally tighten gently until the play is eliminated. Do not over-tighten at this stage, or the suspension may bind. When you are satisfied with the adjustment tighten the pinch bolts. Repeat the adjustment procedure for each link pin. If the shims each side of the torsion arm link are badly worn it will not be possible to eliminate the play. In this case the shims would need to be replaced.

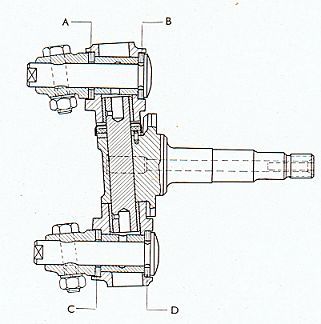

If there is still movement when you rock the wheel after adjustment, get an assistant to look at the joint at the top and bottom of the stub axle, where it fits into the torsion arm link. If movement can be detected here the king pins will need replacing. The link pins will also need replacing as their bushes have to be removed before the king pins can be removed.

To replace the king pins and link pins remove the wheel and brake drums, following the procedure set out in The Historic VW 1'98 entitled, 'Ken C on Wheel Bearings'.

Have two lengths of strong string, or wire handy and then remove the three bolts holding the brake backplate onto the stub axle. These are sometimes secured after tightening with locking wire. Tie the backplate up, so as not to strain the brake hose, or brake cable.

Remove the split pin and nut from the outer track rod end, before using a ball joint splitter to disconnect the ball joint from the stub axle assembly. Remove the pinch bolts, holding the link pins to the torsion arms and using a soft faced hammer, or mallet, hit the torsion arm link to drive out the pins equally.

Using a large vice, press the link pin bushes out of the torsion arm link. You will need a socket slightly smaller than the bush and a piece of pipe slightly larger to push the bush into.

To remove the king pin heat the torsion arm link assembly in an oil bath. A camping stove and an old saucepan is ideal, as it makes quite a smell to do it in the kitchen.

Take care as hot oil can be very dangerous. Heat the assembly to 80 degrees centigrade (175 F) for at least 1/2 an hour. Do not overheat the oil. Press out the king pin, or use an improvised punch, such as an extension bar from a socket set. When the king pin has been removed the stub axle can be separated from the torsion arm link. Press out the bronze king pin bushes.

To reassemble press the new bronze king pin bushes into the torsion arm link. These are pressed in from the inside to the outside of the link. After fitting, you will need to file notches in the upper bush, to match the notches in the torsion arm link. These are to locate the thrust washer cover plate.

Now for the technical bit! The king pin bushes need to be reamed to the exact diameter of the king pin. To do this you will need an adjustable parallel reamer and guide, with a range between 18 and 21 mm diameter. The tapered guide acts as a bush and is located in the opposite bush to the one being reamed. Ream the bushes a little at a time, making very small adjustments to the reamer, until the king pin can be fitted to the bushes with no detectable play.